With our Project Wild E Coyote which is pushing over 590 hp to the rear tires, we are already pushing the limits of the stock transmission. The stock MT-82 was never intended to handle this type of power, meaning it’s living on borrowed time. Before it self destructs, and leaves us riding home from the track in a wrecker, we’re going to replace it with a Tremec T-56 Magnum XL.

The T-56 Magnum XL

Tremec is known for building everything from OEM transmissions to it’s venerable TKO line. Just over three years ago they released the T-56 Magnum line of transmissions. These have features that rival the power handling of the TKO but in a six-speed product designed for the late model performance crowd. It’s taken a few years though for Tremec to come out with a version of this transmission for the late model Mustang crowd. Tremec’s Kevin Ryan explains, “The XL came two years after the standard Magnums. This was partially due to uniquely-tooled castings and packaging considerations.”

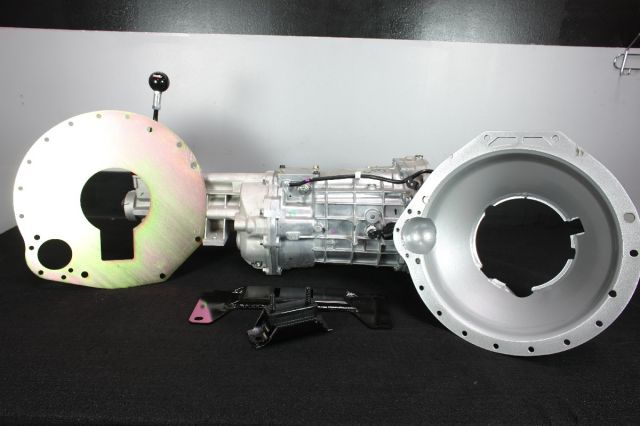

Our T-56 Magnum XL kit included the transmission, shifter, SFI bellhousing, separator plate, transmission mount and cross member.

Some of the features of this transmission include:

- 700 ft-lbs of torque capable right out of the crate

- Designed for cars that weigh as much as 4,500 lbs.

- Nearly 8,000 rpm capable

- Extra long tail shaft (in XL model)

- Two gear ratio sets available

- Includes SFI approved bellhousing

- Includes Tremec short throw shifter.

- Includes correct transmission cross-member for application.

As you can see the T-56 Magnum XL is perfectly suited for cars like Wild E. Coyote. The specs almost look like the transmission was built with the 5.0 in mind. Keep in mind as well that this transmission is also referred to as the TR6060 and is original equipment on the ZR-1 Corvette and the new SRT-Viper. This means that we can expect OEM level fit, shift quality and operation from our transmission for years to come.

The T-56 Magnum XL is also a direct shift transmission, Ryan tells us, “The XL will have improved shiftability. This is because of the direct shift feature. This replaces the semi-remote shift linkage in these cars.”

The XL will have Improved shiftability. This is because of the direct shift feature. This replaces the semi-remote shift linkage in these cars. -Kevin Ryan, Tremec

We opted for the lower geared (numerically higher) T-56 Magnum XL transmission, part number, TUET11940. This transmission features a a gear set of:

- 2.97 First

- 2.07 Second

- 1.43 Third

- 1.00 Fourth

- .80 Fifth

- .62 Sixth

This spread gives us closer shifts, keeping the RPM’s in the sweet spot as we cycle through each gear. It also gives us that extra shove off the line since the Coyote needs a little bit more RPM to get into the power band.

Left: Tear down begins by pulling the covers off the center console, making sure the shifter can drop out with the transmission. Center: Under the car the X-pipe is removed, followed by the factory two piece driveshaft. Far Right: Then the shifter is unbolted from the underside of the car.

To install the kit we actually went outside the Power Automedia shop to Cunningham Motorsports. Owner Ryne Cunningham has done several of the T-56 Magnum XL installations. We’re relying on his experience and expertise with these swaps to guide us through the transition. Cunningham tells us, “Outside the wiring and the programming if you can swap a clutch in a Mustang, you can do this.”

Tear down

Cunningham started by removing the covers for the shifter in the center console and on the floor. This will allow the shifter to come out with the transmission.

Next the exhaust is removed at the X-pipe and all the way back to the mufflers. The factory two-piece drive shaft also must come out to get the transmission out of the car. The starter is disconnected and removed, as well as the electrical connections for the transmission. Next the crossmember and bell-housing bolts are removed, as well as disconnecting the line for the clutch slave cylinder. The transmission is then lowered out of the car.

Left: CMS now uses an impact gun to remove the bellhousing bolts from the block. Center Left: The starter must also be disconnected and removed. Center Right: A transmission jack is used to lower the transmission out of the car. Far Right:A prybar is necessary to provide a small amount of persuasion to the long tube headers. This allows the original MT-82 transmission to slip past the headers without removing them.

The beauty of the S197 Mustang is that even with long-tube headers we don’t have to remove them to get the transmission out. Anyone who’s fought long tubes during a transmission swap knows the pain that they can be. We then removed the clutch and stock flywheel, this completes our tear down.

Clutch Upgrades

The stock MT-82 transmission uses a 23 spline input shaft, while our new T-56 Magnum XL uses a 26 spline shaft. This higher spline count increases the strength of the input shaft by giving the clutch and pilot bearing greater surface area to connect to the transmission.

We just did a torque test on these, if you grind the flywheel, it holds right at 1,000 ft-lbs of torque -Fred Taylor, Mcleod

This input shaft swap also necessitated that we switch out the clutch as well. Since we know Wild E Coyote is an ongoing project, and that we’re going to up the horsepower ante in the future, we chose an Mcleod RXT clutch system. Part number 6932-25 is specifically for the Coyote engine, but we had to specify 26 spline clutch discs, those part numbers are 6924-07, and 6922-07. This twin disc clutch is designed specifically for high power street cars. Mcloed’s Fred Taylor tells us, “We just did a torque test on these, if you grind the flywheel, it holds right at 1,000 ft-lbs of torque.” It is also compatible with the new T-56 Magnum XL’s 26 spline input shaft. In spite of the fact that it’s twin disc, it actually saved us more than 10 lbs over the our stock setup.

Taylor told us, “There are three ways to increase the torque holding capacity of a clutch, greater clamping force, greater surface area, or different material.” By increasing the surface area using two 9 11/16 inch clutch discs the clamping force of the RXT only needs to be around 1800 lbs. This results in a clutch that you can drive easily on the street without chatter, or giving you a charlie-horse in traffic. At the same time you can also give it hell on the track and it will handle whatever abuse is thrown at it. It’s smaller diameter, and lower rotating mass also means that high RPM shifts should be no problem.

Top: We upgraded to a Mcleod RXT twin disc clutch. This clutch offers reasonable pedal effort and incredible holding power. Bottom: In spite of it's twin disc design the clutch actually saves us 10lbs of weight over stock. This weight savings should help the engine rev harder, and make gear shifts easier at high RPM

While we had the transmission out we also replaced the original hydraulic clutch release bearing with a new OEM one from Downs Ford, it is Ford part number BR3Z-7A508A. There was actually nothing wrong with the operation of the one currently installed. However, with 45,000 miles on it, and more abuse to come, we figured replacing this part now would help us avoid a potential headache later.

Installation

Cunningham began installation by installing the new transmission separator plate that came with a transmission. This plate and bellhousing were ground just slightly to allow proper clearance for our long tube headers.

Left: The separator plate goes on first. Center: Cunningham puts red thread locker on the flywheel bolts then installs the Mcleod flywheel and adapter ring. Right: Using an old input shaft as an alignment tool, the clutch assembly is installed.

Next the flywheel that was included with our RXT clutch kit, followed by the rest of the RXT clutch kit. Aligning the RXT clutch adapter ring with the flywheel.

With the clutch installed the bellhousing is next. This bellhousing goes on before the transmission is installed, it should be bolted in place before installing the transmission.

Clutch Line Upgrade

We put a call into JPC Racing and ordered one of their clutch line upgrades, part number, JPC-CLK. This -4 AN stainless braided line replaces the factory rubber one that runs from the metal line on the clutch master cylinder to the plastic junction that feeds fluid to the clutch release bearing. This line’s increased size provided more volume from the clutch master cylinder to the clutch release bearing. Also like having a stainless braided brake lines improves braking performance, this should help us with faster clutch response, improved clutch pedal feel, and less flexing.

Getting the Trans in Place

Before installing the transmission Cunningham attached our new Tremec shifter. This shifter provides crisp positive shifting action, while reducing noise, vibration and harness. The transmission is then carefully aligned with the clutch and pilot bearings and slid into place. This is where a lot of first timers will make a mistake.

Do not let the transmission hang by the input shaft. If you don’t have a suitable jack, have a buddy help you. The input shaft is designed to take high rotational loads, but allowing the transmission to hang on it could bend it. A bent input shaft can cause a vibration, noise, or even input shaft failure. Slide the transmission all the way in, and onto the bellhousing without applying weight to the input shaft. From there Cunningham installs the bolts that secure the transmission in place.

Top: The T-56 Magnum XL came with a new Tremec shifter. The direct shift design of the transmission should provided faster, crisper shifts and better shift feel than the stock semi-remote setup in spite of our after-market shifter. Bottom: Our kit includes this transmission cross-member and mount which bolts to the factory location and is the final step in physically installing the transmission.

We then installed the new cross member that Tremec supplies with this kit. This locates the transmission mount in the appropriate spot and supports the transmission’s weight properly.

Driveshaft Upgrade

From almost day one of the S197 enthusiasts lamented about the two piece drive shaft. With over 590 hp making it to our rear tires, an upgrade in this area has been long overdue for Wild E Coyote.

The extended length of the tail shaft on our T-56 Magnum XL also necessitates a shorter drive shaft as does its sip yoke design verses the factory MT-82’s fixed flange, bolt-on yoke design. For our driveshaft we turned to Dynotech Engineering. They supplied us with an aluminum drive shaft of the correct length for our install.

Left: Cunningham weighs our stock two-piece driveshaft which scaled at 37 pounds, Center: Our Dynotech one piece aluminum driveshaft weighs just 16 pounds. Far Right: You can see the physical difference in size between the two drive shafts.

Our Dynotech shaft is made from 6061 T-6 aluminum tubing, .125 inches thick. Dynotech’s Steve Raymond, tells us, “Our general rule of thumb for 3.0” and 3.5” diameter shafts respectively would be, up to 400 hp and 900 hp.”

Dynotech does not have a specific part number for this driveshaft. They instead have told us to simply call and specify that you need a driveshaft for a 2011 Mustang for a Tremec T-56 Magnum XL swap. With that information they’ll be able to send you what’s needed.

We also had them install the AEM Electronics Dyno-Shaft slip yoke, which contains the Dyno-Shaft strain gauges that provide data for the Dyno-Shaft system.

Our Dynotech driveshaft is not only stronger than the stock two piece system, but also lighter as well. It saved us another 21 pounds over the stock unit it replaced, which is 33% less weight than our original. While rotating mass on this small of a diameter is not as critical to overall performance in our application, every bit of overall vehicle weight saved is always a positive.

Top: We will be discussing AEM's Dyno-Shaft in an upcoming article. We went ahead and installed the hardware portion of it while we were performing our transmission swap. Bottom: The Dynotech driveshaft slips into the transmission and bolts to the pinion flange on our rear differential.

Cunningham installed the driveshaft with the new slip yoke and bolted the differential side up in the original location.

Finishing Up

Where’s the Signal

Cunningham has developed a method for converting the OEM three wire speed sensor to a two wire setup that comes on the T-56 Magnum XL. He was able to do this because a 2011 GT500 actually uses a T-56 Magnum XL transmission. After sorting out the wiring, he compared the software differences and corrected them via SCT software. Filling in the blanks worked, and Cunningham claims to have come up with the software solution in less than 20 minutes time.

Cunningham has developed a method for converting the OEM three wire speed sensor to a two wire setup that comes on the T-56 Magnum XL. He was able to do this because a 2011 GT500 actually uses a T-56 Magnum XL transmission. After sorting out the wiring, he compared the software differences and corrected them via SCT software. Filling in the blanks worked, and Cunningham claims to have come up with the software solution in less than 20 minutes time.

There are two options for wiring the speed sensor on this particular swap. Ford originally used a three wire setup for the ’11 Mustang GT, however the T-56 Magnum XL uses a two wire. Cunningham has figured out how to make the harness a two wire affair and reprogram the car’s computer accordingly via SCT software. The 2011 GT500 transmission software was the source for this solution, “I compared the two, filled in the blanks, and viola it worked,” says Cunningham.

The skip shift wire is not used and can be capped and moved out of the way, there’s no veiled attempt at skirting gas guzzler taxes here.

Home Stretch

Cunningham now reinstalled our exhaust and bled the clutch hydraulic system. If you’re doing this at home, you’ll need a buddy’s help to do the bleeding process unless you have a one man bleeding system. The transmission was filled with standard ATF fluid per Tremec.

Back inside the cabin, Cunningham had to slightly grind the shifter’s top nut to get proper clearance for the first gear position. With the shifter clearance squared away, he then reinstalled the console components and covers, and fired the car up for a drive.

With our new transmission in place we can take Wild E Coyote out for a drive or to the track with some renewed confidence in our drivetrain. The Mcleod RXT clutch provides great pedal feel for such an extreme piece of hardware. We’re also impressed by the slick shifting feel and the different ratios offered by the T-56 Magnum XL package. We’ll be curious to see how the car feels on the track in the very near future.

Part Numbers Used:

Tremec Transmission

- T-56 Magnum XL Transmission Package: TUET11940

Mcleod

- RXT Clutch Kit with Flywheel: 6932-25*

- *26 Spline clutch discs necessary. Part numbers: 6924-07 and 6922-07

Dynotech Engineering

- Tremec Magnum XL Driveshaft

JPC Racing

- Clutch Line Upgrade: JPC-CLK

Downs Ford

- Ford Clutch Release Bearing (slave cylinder):BR3Z-7A508A